The company you probably once knew for its calculators and computers is still around—developing critical components for electric-car chargers.

Texas Instruments is marketing a new generation of gallium nitride field-effect transistors (GaN FETs), which the company claims can double the power density of onboard chargers for electric cars, while increasing efficiency.

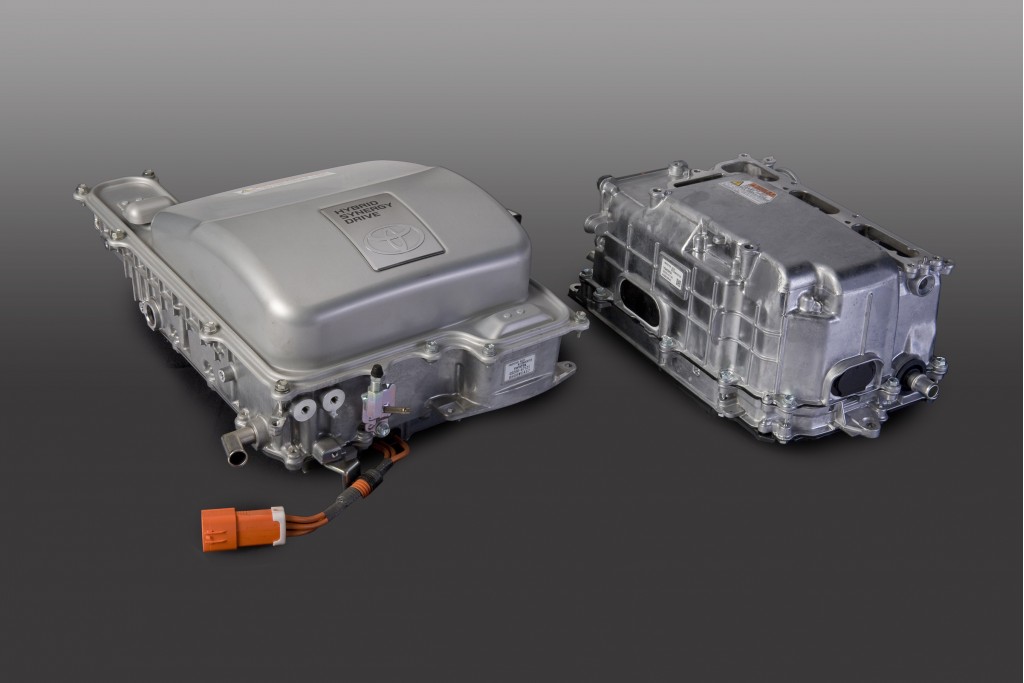

Use of GaN FETs can also reduce the size of onboard chargers and DC-DC converters by up to 50% compared to current hardware, TI claims.

The company hasn't discussed any automaker partnerships, but it said that it is making pre-production versions of the hardware available to purchase for evaluation purposes.

Toyota Prius - 2nd and 3rd gen inverters

TI's push fits right in with the rapid fortification of the electric-vehicle supply chain, in which a number of top-tier tech companies and suppliers are eager to get a foothold.

Last year, automotive supplier Delphi announced a new inverter to support 800-volt charging, and confirmed in September that it would supply the component to an unnamed automaker for future luxury cars.

Many upcoming electric cars are expected to use 800-volt charging, including Audi and Porsche models based on the Volkswagen Group Premium Platform Electric (PPE) architecture, General Motors vehicles using the BEV3 platform, and models from Mercedes-Benz and Hyundai/Kia/Genesis.

2018 Nissan Leaf

German supplier Robert Bosch—a bulwark for diesel support—took control of electric-motor maker EM-motive last year, and also announced an alliance with Powercell Sweden AB to co-develop hydrogen fuel cells for cars and trucks, which Bosch would manufacture.

As TI tries to shrink onboard chargers, the same rapid downsizing is happening on the outside of electric cars, too, with charging hardware.

In 2018, researchers at North Carolina State University unveiled a 50-kilowatt DC fast charger they claimed cost half as much as conventional units, and was only 1/16th the size. However, it was a research project and thus not production-ready.