By far the most most important part of any electric car is the battery. It’s also one of the youngest technologies because, while first conceived in the 1800s, the first commercial lithium ion batteries were made by Sony in 1991.

And another thing: we hear lots of confusing names for them, but how different are they? For instance, is a lithium-iron-phosphate battery a lithium ion battery or something else?

Despite the fancy names, they are all lithium ion batteries, they all work the same way and they all have the same basic components in them.

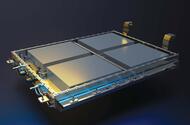

Batteries are actually hundreds of battery cells, each producing a few volts and packed together in a casing to provide the energy an EV needs.

Each cell contains two electrodes: a positive cathode and a negative anode. There’s a non-conductive separator between them, made of plastic or ceramic, and a thin layer of liquid electrolyte.

Cells can be thin and flat like an oversize After Eight mint or rolled up to make a cylindrical or prismatic format, but they all contain those four things.

The one thing that does change in a lithium ion battery is the formulation of the cathode. Nickel-manganese-cobalt (NMC) and lithium-iron-phosphate (LFP, with the ‘F’ standing for ‘ferrous’) are the two most common types of EV battery.

Both names describe the mix of chemicals used to make the cathode; the anode is always carbon-based and usually made from graphite.

The battery industry likens the mixing of chemicals to baking a cake, but the truth is that fewer ingredients are used in a lithium ion battery cell than a Bake Off show-stopper.

The cathode is made by mixing the chemicals into a paste, which is spread onto aluminium foil and dried; the carbon anode is made with a graphite paste spread on copper foil. Different formulas give different battery characteristics.

NMC batteries can store more energy for range and cobalt is good for power density, but the cheaper LFP battery has no expensive nickel or controversial cobalt. It’s more stable, too.

They all work the same way, though. During charging, lithium ions in the cathode travel through the electrolyte and separator to the carbon anode. When the battery is in use and discharging, the ions travel back to the cathode.

Should you be worried about which chemistry is used by the EV you’re about to buy? If sustainability is a criterion, batteries free of heavy metals such as nickel and cobalt have arguably better environmental credentials.

But what matters day to day are the and performance figures, not how the manufacturer arrived at them.