Motors for the brand's new PPE architecture are 20% lighter, use 30% less space and reduce drag

Most of the major manufacturers have already revealed technology road maps for the next decade that involve a steady move away from ICE to pure-electric drivetrains.

Anyone who’s ever visited a modern engine plant will appreciate just what a huge task that must be and how no manufacturer would take the decision lightly.

There’s more to it than simply the cost and a shift in strategy: there are cultural implications too. Skills built up in the industry over 100 years for the development of complex ICE powertrains will be replaced by a different set altogether.

Audi’s facility at Gyor, Hungary, is billed as the largest powertrain plant in the world and it’s where the firm is producing all the electric drivetrains for its new Premium Platform Electric (PPE), developed with Porsche for larger cars.

The plant makes both the drive motors and axles for Audi’s own cars and the motor side involves a complete shift away from traditional powertrain manufacturing. The casting and machining of engine blocks, boring cylinders and then assembling the dozens of moving parts has given way to, on the face of it, the mechanically simpler alternative of the stators and rotors of electric motors.

Audi says it has made 500,000 electric motors since 2018, and although there may be fewer moving parts in the end result, there are still lots of parts to assemble. There are 15 automatic bending machines to make the U-shaped ‘hairpin’ windings that in modern motors replace the continuous lengths of wire in traditional windings.

Each stator (which forms the coils of a motor surrounding the revolving rotor with its permanent magnets) comprises 140m of copper wire in those hairpin windings, which are joined into continuous lengths with 235 laser welds. More pressings and fewer bolted fasteners than combustion engines mean more robots can be used for assembly.

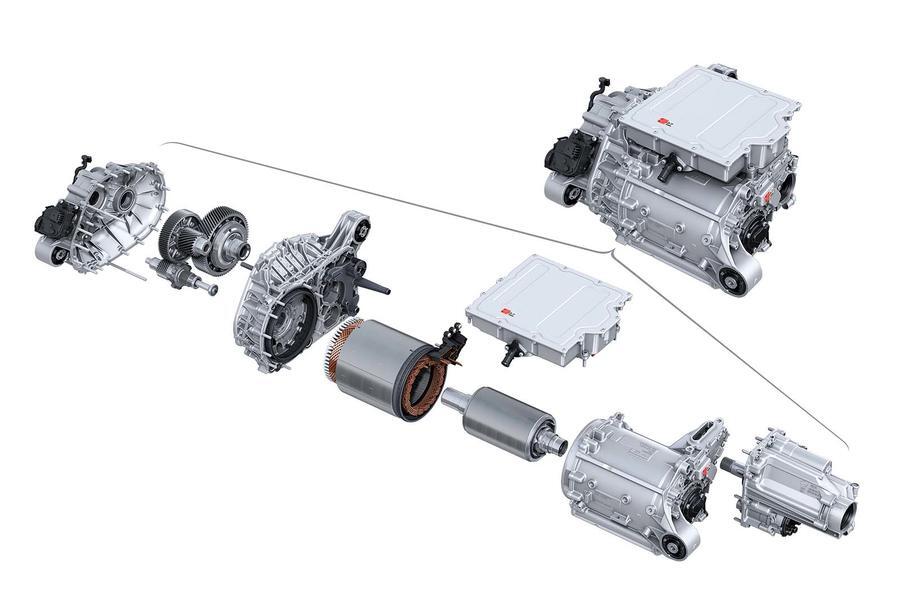

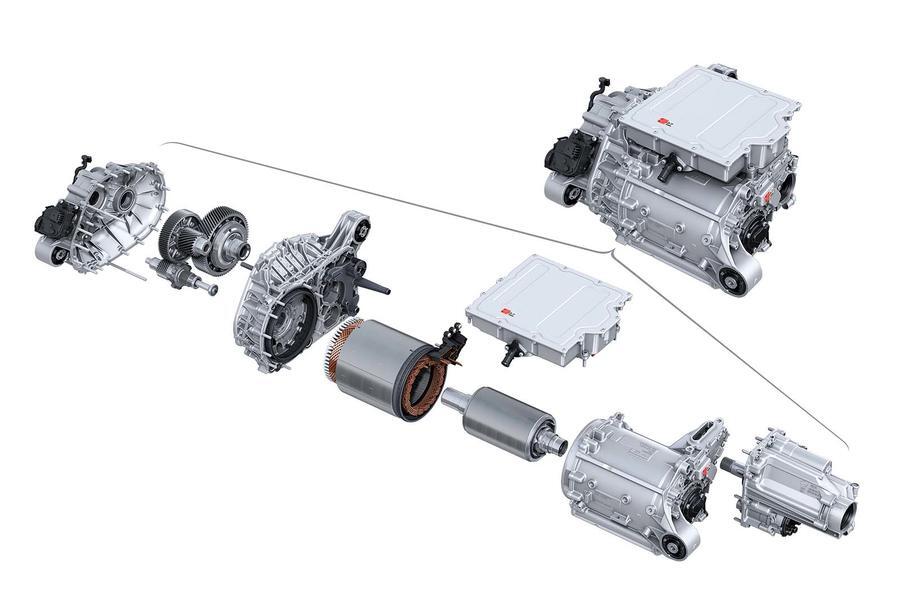

The electric powertrains are elegantly modular and torque output for different vehicles is changed simply by making the motors longer or shorter. Torque at the wheels and maximum speed are varied by changing the ratios of the gear pairs in what, by comparison with ICE, are simple transmissions.

There might be a perception at consumer level that EV technology is still in its infancy, but it has already evolved in the past few years and is moving fast. Audi says these new PPE motors take up 30% less space in the car than earlier ones and are 20% lighter.

The hairpin winding technique allows for a ‘fill factor’ (new jargon comes with new technology) of 60% compared with 45% for conventional windings. That means more windings in the same space, equating to more torque from the same-size motor.

Oil-cooled rotors have improved efficiency too, with losses caused by drag reduced by 50%. The power-to-weight ratio for PPE motors is now 60% higher than for Audi’s first-gen electric motors.

So on the face of it, while electric motors may sound dull compared with internal combustion engines, a peek under the skin reveals they’re anything but.